Discover our selection of heat exchanger recuperators in our online shop. Our products are designed to recover heat in various industrial processes, offering maximum energy efficiency. With an innovative design and high-quality materials, our heat exchanger recuperators guarantee reliable, long-lasting performance. Order now for fast delivery to your home or business.

RRE (Rotary wheel heat and energy recovery exchangers)

RRE (Rotary wheel heat and energy recovery exchangers)

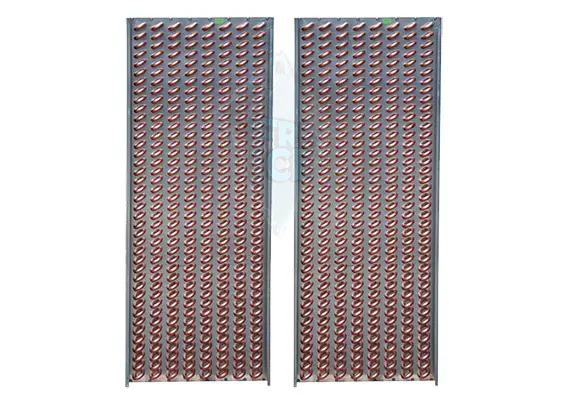

As the product rotates, fresh air and exhaust air pass through the voids between the flat and waffle fins of the exchanger and heat and/or energy transfer takes place.

In our product range, there is the sensitive type (condensation) and the total energy type (absorption).

In the case of the condensation type, there is only heat transfer between two air currents, and moisture transfer only occurs in winter due to condensation.

In the absorption type, heat and energy (humidity) are transferred between two air currents in summer and winter.

The general properties of rotary heat exchangers include high efficiency, an insignificant distance between two air streams, a low level of contamination and no moving parts. Technical data such as heat and energy recovery, moisture transfer, efficiency, pressure drop, flow rate and risk of freezing in winter are calculated using high-precision software developed specially for this purpose in-house.

In condensation types, the moisture in the exhaust air condenses on the surface of the fins in winter. This can cause ice to form, and freezing must be avoided to prevent a reduction in energy efficiency and damage to the heat exchanger. Although the risk is lower with absorption types, it should be taken into account.

As the standard internal length of the wheel is 200 mm, the height of the waffle corrugations is 1.7 mm and 2.1 mm. Products with different internal lengths (250 mm) and wave heights (2.5 mm) can be produced on request.

Mechanical properties:

In the condensation types, the fins are made of aluminium as standard. On request, industrial epoxy or hydrophilic pre-coating can also be used for the fins. In the absorption types, the fins are coated with aluminium adsorbent. Frames and covers are manufactured in galvanised sheet metal or aluzinc on request. Products are manufactured without a purge section as standard, but a purge section can be added on request. The rated speed is 12 rpm for the condensing type and 18 rpm for the absorption type. A 230V 1Ph 50Hz motor is used as standard, 400V 3ph 50Hz on request, and different types of motor can be added to the system.

Nomenclature: RRE 1000 200 2 CA

RRE: Rotary recovery exchanger

1000: Outside diameter of wheel, max 3200 mm

200: Internal length, 200 mm standard, 250 mm optional

2: Height of waffle corrugations, 1: 1.7 mm or 2: 2.1 mm standard, 2.5 mm optional

CA: Condensation type, S3: Absorption type

L x W x H: Dimensions mm

1000: Outside diameter of wheel, max 3200 mm

200: Internal length, 200 mm standard, 250 mm optional

2: Height of waffle corrugations, 1: 1.7 mm or 2: 2.1 mm standard, 2.5 mm optional

CA: Condensation type, S3: Absorption type

L x W x H: Dimensions mm

Rotoseal sealing system;

It is important to minimise air leakage in rotary heat exchangers and sealing systems are used for air sealing. Brushes are very effective in sealing systems. They are strong, durable and easy to replace. The position of the brush can be adjusted with screws. Brush sealing systems are used around the perimeter of the rotating wheel and across the central beam of our products.