Discover our selection of heat exchanger recuperators in our online shop. Our products are designed to recover heat in various industrial processes, offering maximum energy efficiency. With an innovative design and high-quality materials, our heat exchanger recuperators guarantee reliable, long-lasting performance. Order now for fast delivery to your home or business.

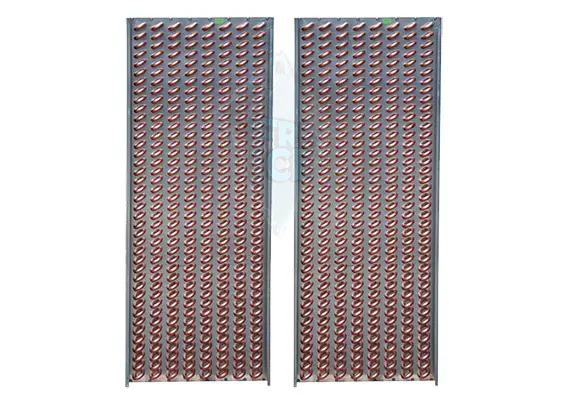

PHE Cross (Plate heat recovery exchangers)

PHE Cross (Plate heat recovery exchangers)

Multiple air channels formed by fins generate heat transfer between the exhaust air and the fresh air, resulting in heat recovery. Although there are sensible and total energy types, Karyer only manufactures sensible types. There is heat transfer between the two air streams, but no moisture transfer. Exhaust air and fresh air cross the exchanger. The fresh and exhaust air streams are close to each other, they mix at low flow rates and there are no moving parts. These are just some of the typical properties of this heat exchanger.

Technical values such as heat recovery, temperature efficiency, air pressure drop on both sides and the risk of water freezing in winter are calculated in-house using specially developed software.

In winter, the humidity in the air condenses on the fins of the coils. To avoid loss of energy efficiency and damage to the heat exchanger, the water in the condensate must not freeze.

The APHE series of plate heat exchangers is certified by EUROVENT.

Mechanical properties:

The fins are made of aluminium as standard. On request, marine alloy aluminium, industrial epoxy or hydrophilic pre-coating can also be used for the fins. The frame can be made of aluminium with a special profile, and the covers can be made of galvanised sheet or aluminium.

Nomenclature: APHE A 20 5.3 034 N C

APHE: Description of the cross-flow plate heat exchanger model

A: Aluminium E: Epoxy coated aluminium H: Hydrophilic coated aluminium M: Marine aluminium alloy

20: Edge size 20, 30, 40, 50, 60, 80 cm etc.

5.3: Fin pitch mm, from 3 to 8 mm depending on edge size

034: Fin length cm, up to 200 cm

N: Type of corner seal N: Standard S: Special C: Structure of corner profile

A: Aluminium E: Epoxy coated aluminium H: Hydrophilic coated aluminium M: Marine aluminium alloy

20: Edge size 20, 30, 40, 50, 60, 80 cm etc.

5.3: Fin pitch mm, from 3 to 8 mm depending on edge size

034: Fin length cm, up to 200 cm

N: Type of corner seal N: Standard S: Special C: Structure of corner profile

Application examples:

Cross-flow plate heat recovery exchangers can be connected in series to increase efficiency.

In the case of different air flow rates, parallel application, as shown below, can be applied to keep the pressure drop values on both sides at an acceptable level and to improve efficiency.

Cross-flow plate heat recovery exchangers can be used for pre-cooling and reheating in dehumidification systems.