Discover our selection of heat exchanger recuperators in our online shop. Our products are designed to recover heat in various industrial processes, offering maximum energy efficiency. With an innovative design and high-quality materials, our heat exchanger recuperators guarantee reliable, long-lasting performance. Order now for fast delivery to your home or business.

PHE Counter (Plate heat recovery exchangers)

PHE Counter (Plate heat recovery exchangers)

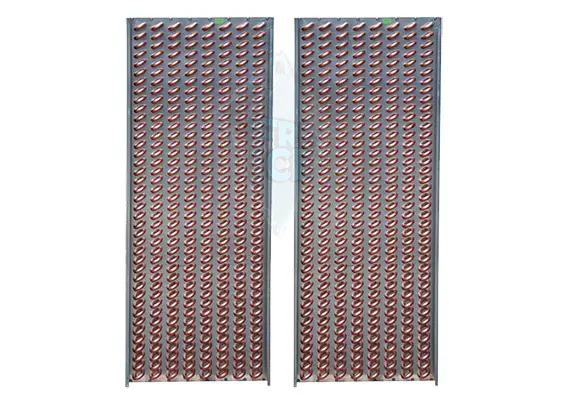

Multiple air channels formed by fins generate heat transfer between the exhaust air and the fresh air, resulting in heat recovery. This is the sensitive type. There is heat transfer between the two air streams, but there is no moisture transfer. It is advantageous not to have moisture transfer for this type. Exhaust air and fresh air pass through the heat exchanger mainly from opposite directions.

Technical values such as heat recovery, temperature efficiency, air pressure drop on both sides and the risk of water freezing in winter are calculated in-house using specially developed software.

The width (W) and height (H) of the heat exchangers are fixed, while the length (L) and pitch (h) may vary.

Mechanical properties:

Types L, U, etc. are available for the airflow side.

The fins are made of aluminium as standard. On request, marine alloy aluminium, epoxy or hydrophilic industrial pre-coating can also be used for the fins. Covers can be manufactured in galvanised sheet metal, or in aluzinc and aluminium alloy on request.

The fins are made of aluminium as standard. On request, marine alloy aluminium, epoxy or hydrophilic industrial pre-coating can also be used for the fins. Covers can be manufactured in galvanised sheet metal, or in aluzinc and aluminium alloy on request.

Nomenclature: UPHE A 40 14 5 050 L N C

UPHE: Model description of cross flow plate type heat recovery exchanger

A: Aluminium E: Epoxy coated aluminium H: Hydrophilic coated aluminium M: Marine aluminium alloy

40: Edge size (Width) cm

14: Height cm

5: Fin pitch mm

050: Fin length cm

L: Air flow diagram

N: Type of corner seal (mastic) N: Standard S: Special

A: Aluminium E: Epoxy coated aluminium H: Hydrophilic coated aluminium M: Marine aluminium alloy

40: Edge size (Width) cm

14: Height cm

5: Fin pitch mm

050: Fin length cm

L: Air flow diagram

N: Type of corner seal (mastic) N: Standard S: Special